Flexible Filling Solutions for Syringes and Cartridges

Modular designs such as the Bausch+Ströbel VarioSys® allow for component flexibility and product segregation without the expense of separate filling lines. Solutions that enable product adaptability and scale-up without compromising quality are critical, which is why Grand River Aseptic Manufacturing invested in the Bausch+Ströbel VarioSys® flexible filling line with SKAN isolator.

The Features

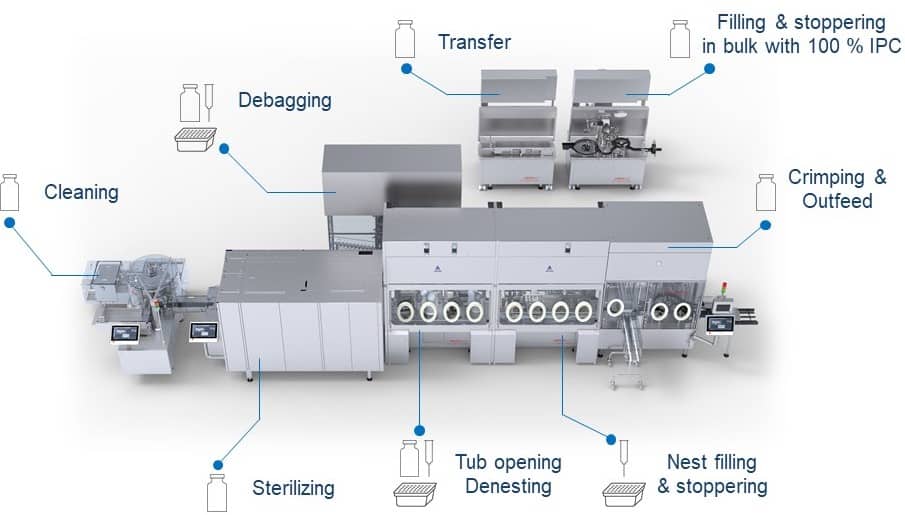

- Syringes – Nested filling process

- Vials – Bulk filling process (RTU Vials or Bulk)

- Isolator – Connected with the module via inflatable gasket

- Exchangeable modules using “L-flange” technology

The Benefits

- Modular isolator with fast and easily exchangeable filling modules allows rapid changeover (<30 minutes) from one process to another.

- Maintenance, cleaning, and set up of filling modules occurs outside the isolator, thus optimizing filling line utilization.

- Ideal working conditions for processing highly active substances with safe change filter system to ensure containment.

- Optimized decontamination cycle for each module via integrated SKANFOG® technology, which reduces decontamination time.

- Minimizes drug substance (DS) loss and provides maximized batch yields via Bausch+Ströbel ADVANCEDfill zero reject technology.

- Modules can be customized for other activities such as sterile compounding or filling of novel product containers. Larger process equipment can be interfaced with pressure-tight flanges.

GRAM’s VarioSys World

- Learn how GRAM’s flexible filling technology works with sterile injectable products in this 4-part video series: GRAM’s VarioSys World.